Our Thermal Spray Products and Services

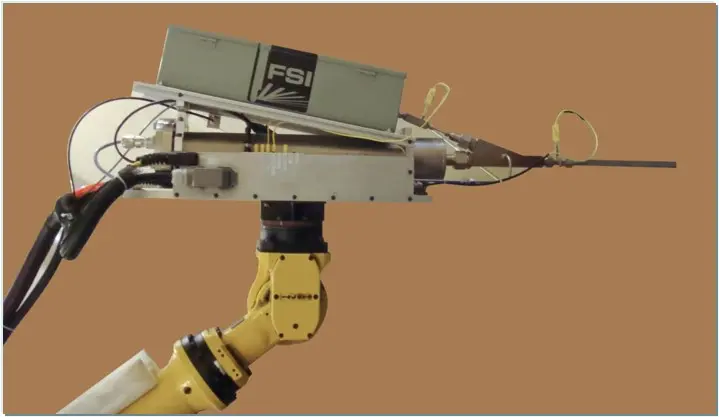

Plasma Transferred Wire Arc (PTWA)

Plasma Transferred Wire Arc (PTWA) is a unique manufacturing process that can deposit a coating on the internal surface of a cylinder, or on the external surface of a part of any geometry. Any conductive wire can be used as the feedstock material, including “cored” wire. Refractory metals as well as low melt materials are easily deposited using this technology.

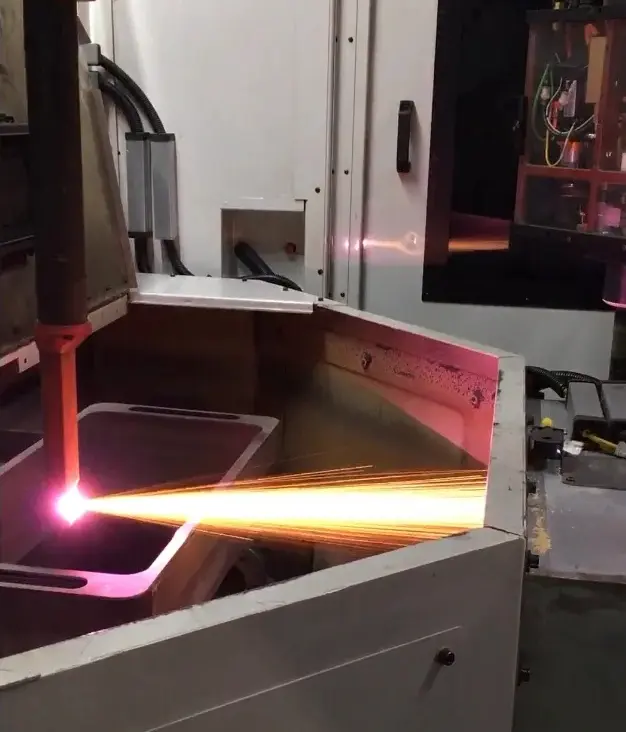

Twin Wire Arc Electrospray

Flame-Spray has been providing twin wire arc systems since 1964. The Twin Wire Arc Electrospray system has been engineered to operate in a robust, reliable, and economical manner to produce high-quality coatings at high deposition rates. The sturdy front-drive system features long-life components designed for continuous OEM applications. Hand-held models are also available. Electrospray can be used with a solid or cored feedstock wire with diameters of 14 ga., 11 ga., or 1/8 in. wire. The controls of the Electrospray system allow the user to control air pressure, spray voltage, and wire feed rate with easy local or remote, PLC, or pendant controls. The power supply is an advanced solid-state design available in 350, 450, and 600 amp models. All power supplies are rated at 100% duty cycle and allow for continuous operation. Both United States and European style electrical inputs are available.

Electrospray coating applications include OEM, repair work, wear-resistance, and anti-corrosion coatings. Materials such as zinc, aluminum, copper, bronze, steel-based alloys, and nickel-based alloys in both solid and cored wire form are examples of materials that can be sprayed using the Electrospray process.

Kinetic Spray

Kinetic Spray is a type of cold spray process which uses heated high pressure gas to accelerate metal powder through a super sonic de Laval nozzle to achieve high velocity particles. This results in ballistic impingement of these particles upon a suitable substrate to form a coating or a free-standing structure.